Understanding Glass Fabrication: From Raw Material to Custom Solutions

Glass fabrication is the process of creating glass products from raw materials and preparing them for specific uses. Whether for architectural projects, decorative glass elements, or commercial installations, glass fabrication offers customization to fit unique design and functionality needs. This guide explains the glass fabrication process, types of glass commonly fabricated, and applications in residential and commercial settings.

What is Glass Fabrication?

Glass fabrication involves cutting, shaping, and treating glass:

- Cutting and Shaping: Glass is precisely cut and shaped to fit design specifications.

- Tempering: Glass is heated and cooled for added strength.

- Laminating: Layers of glass are bonded for additional safety and soundproofing.

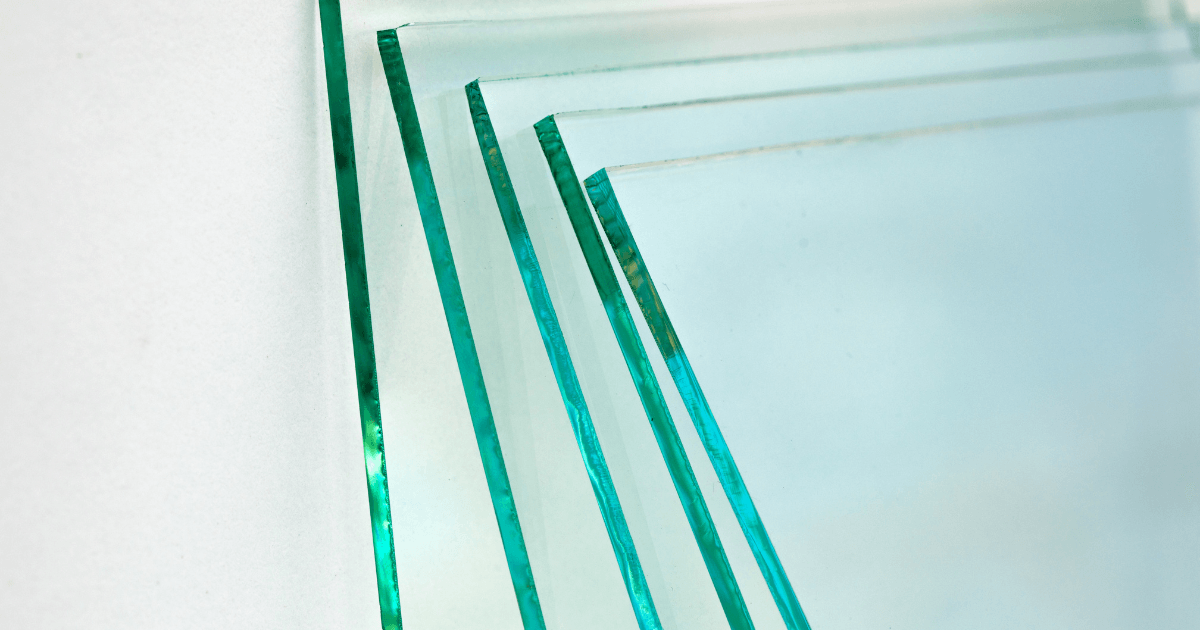

Glass fabrication process with cutting and shaping.

Types of Fabricated Glass

Common types of fabricated glass include:

- Tempered Glass: Ideal for safety and impact resistance.

- Laminated Glass: Common in soundproof and security applications.

- Decorative Glass: Customizable for aesthetic appeal in homes and offices.

Applications of Fabricated Glass

Fabricated glass is used in:

- Residential Windows: Enhances energy efficiency and security.

- Commercial Storefronts: Provides durability and aesthetics.

- Interior Glass Partitions: Used for style and functionality in offices.

Glass Fabrication vs. Glass Products

For ready-made options, consider our selection of glass products to find the right fit.